Discovering cement

Cement History

A cement is a binder, a substance used for construction that sets, hardens and adheres to other materials, binding them together. It is made from natural materials for a purpose to substitute or wood on building construction such as houses, roads, bridges, dams, hospitals, temples as well as architecture and structure of the building. The structures which are made from cement will be enduring throughout their lifetime.

Raw Materials Used In Cement Manufacture

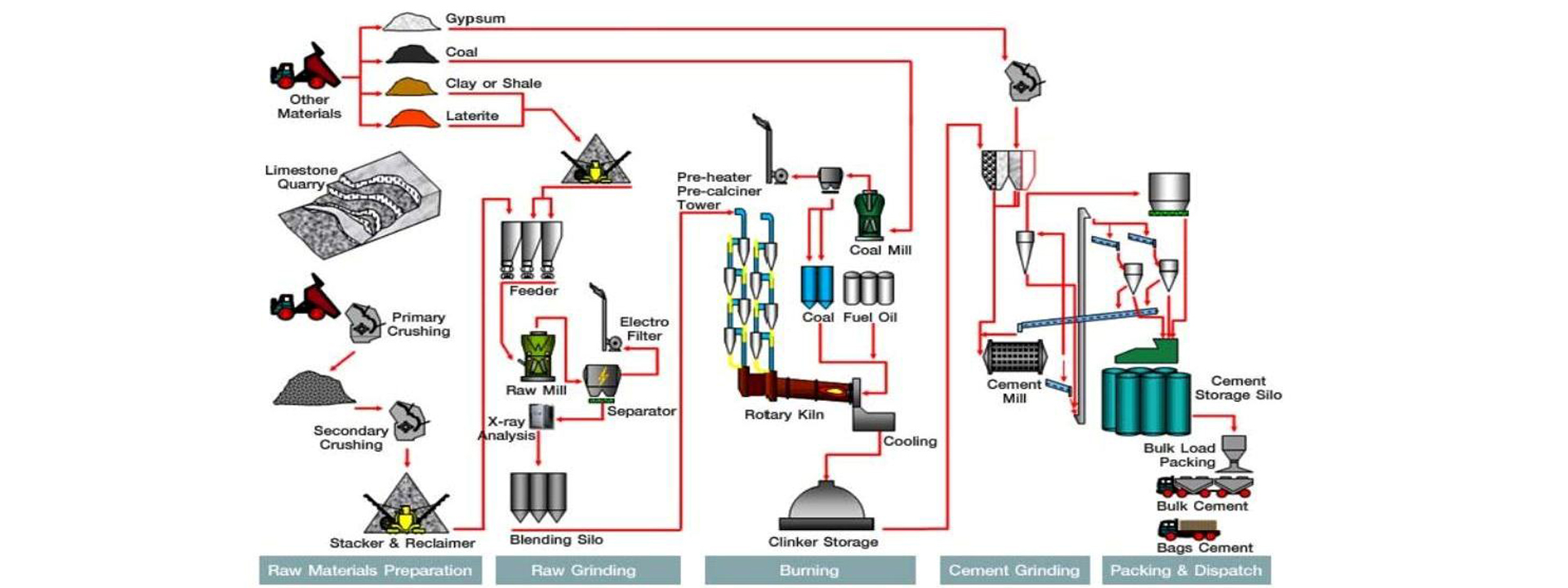

Clinker is the prior produce of cement. It is made from natural raw materials, i.e. limestone, shale, clay and laterite or iron ore. Limestone is the major raw material and is mostly used in cement manufacture process. All raw materials have to pass the coarse grinding stage to get the size as required and then are proportionally blended in the ratio as determined by Quality Control Section before grinding into a smaller size. In this stage quality control is exercised by emphasizing on fineness while chemical element ratio of raw materials are adjusted through analytical results by computerized x-ray equipment. The quality raw material powder is then carried to store in silos waiting for calcination process.

Calcination to Convert Raw Materials into Clinker

This process starts from conveying raw material powder from silos to a pre-heater tower for heat exchange. Raw materials powder will flow downwards to exchange heat with the hot gas from a kiln. When the temperature gets higher to be approximately 850 degree Celsius limestone will be disintegrated and yields carbon dioxide (CO2). Such reaction is called "De carbonization." Afterwards the raw material powder that is already passed the De carbonization process will be conveyed to a kiln. When the temperature gets higher to approximately be 1,450 degree Celsius, crucial compounds will arise, i.e. Tricalcium Silicate (C3S), Dicalcium Silicate (C2S), Tricalcium Aluminate (C3A) and Ferrite (C4AF) which will be combined together and convert into clinker. The clinker will flow out of a kiln through a clinker cooler in order to quench or rapidly lessen the temperature to approximately be 100 degree Celsius prior to be conveyed to store in clinker silos.

Cement: Before Delivering To Customers

Clinker from silos will be conveyed into cement mill for grinding and blending with gypsum, limestone, fly ash and cement additive in the ratio designed to fit for each type of cement. Such cement grinding stage is closely controlled in both chemical and physical attribute to get a constant product quality and meet the customer's requirements. After passing the quality inspection process it will be conveyed to store in cement silos in order to be distributed to the customer.